Systems & Design Engineering

Bell Telephone Laboratories coined the term Systems Engineering back in the 1940s when it was determined that individual engineering projects when put together do not necessarily create the same thing as a desired complex system.

Engineering is traditionally decompositional. That is, to understand the whole, it first has to be separated into its parts. Upon mastering the individual parts they can be reassembled whereupon the engineer can become a master of the whole.

The systems engineering approach is quite the opposite where any one part cannot be understood without the context of the whole. That is, with traditional engineering the parts are understood first but with systems engineering, the whole is understood first and then the role of each part is mastered.

An engineered solution combines components that work in union to collectively perform a useful function. Employing multiple disciplines, systems engineering focuses on how to design, integrate, and manage complex systems over their life cycles.

The discovery process is of the utmost importance - finding out the real problems that need to be resolved and identifying the potential drawbacks and possible failures in order to come up with the most proficient and cost effective solutions.

Systems engineering ensures that all likely aspects of a project or system are considered when integrating into the whole.

Complex System Design

Developing conceptual and detailed designs ensure a product functions, performs, and is fit for its purpose. The greater the complexity, the more important a truly engineered design becomes.

-

Detail

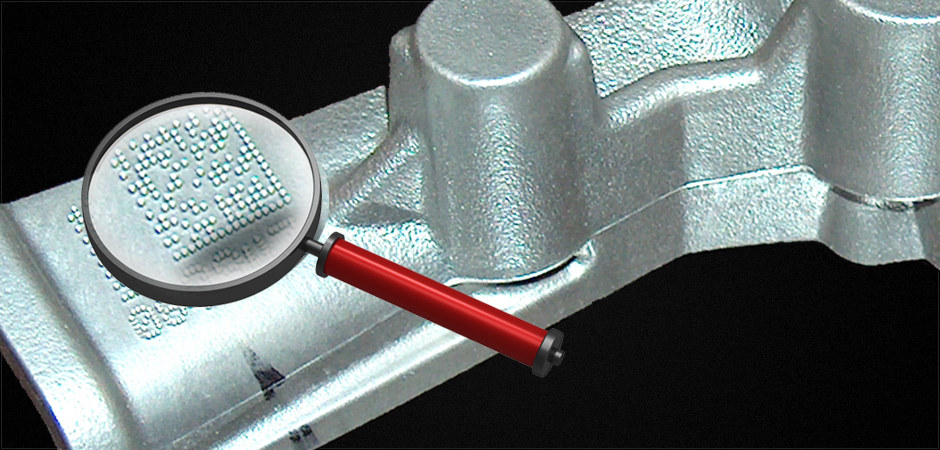

DEC is known for its ultimate attention to detail.

-

Experience

We have over 100 combined years of experience in system design.

Systematic Integration

Methodical incorporation of hardware and software pertinent to the facility ensures that the client will be able to work on the finished system without having to replace their tools currently in place.

-

Quality

DEC is known for not stopping until the project is fulfilled and the client is satisfied 110%.

-

Multiple Disciplines

When it comes to integrating new systems into legacy plants, we have the experience of electronics, hardware & software to get the job done.

Ongoing System Management

With increasingly complex systems, having a strong management system in place is imperative. We have managed clients over decades, ensuring the integrity of the design remains consistent through changes in hardware and software over the years.

-

Loyal

We take pride in maintaining programs and systems in order to keep our clients happy.

-

Responsive

DEC maintains their fleet of customers due to continual top-notch service.